CHEMTROL PC7000 Chem/Filter Controller With Ppm

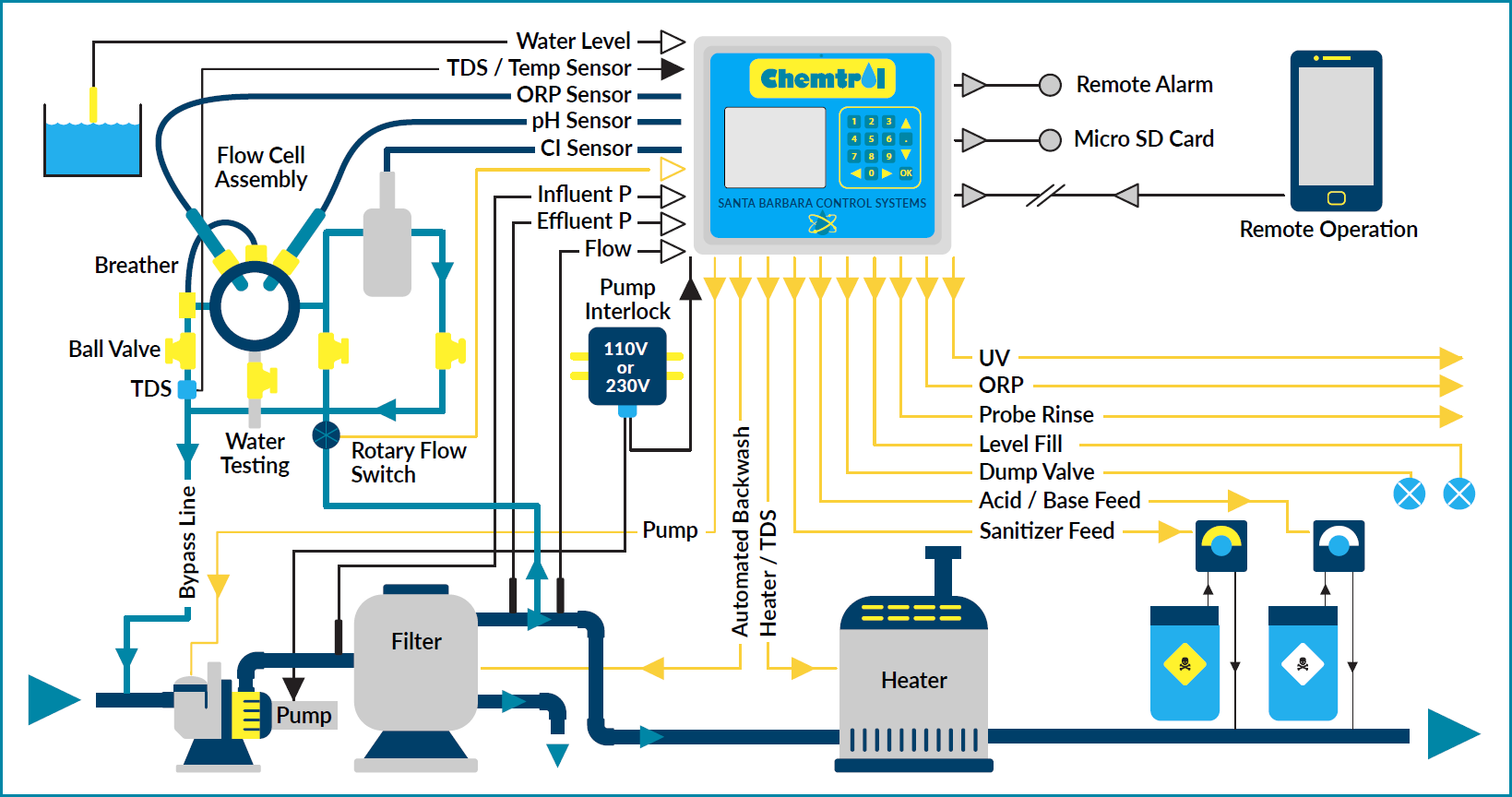

The CHEMTROL® PC7000 combines advanced water-chemistry control with filtration/pump automation in one panel—and adds direct free-chlorine (PPM) measurement for precise, code-friendly dosing. It continuously monitors PPM free chlorine, pH, and temperature, then drives chemical feed using adjustable setpoints with proportional/PID control, dose limits, and safety lockouts to prevent overfeed. On the mechanical side, the PC7000 sequences pumps, filters, valves, and heater interlocks so backwash cycles and daily operation run the same way every time—reducing manual checks and protecting equipment.

Designed for commercial pools, spa banks, and aquatic centers, the PC7000 streamlines operations with on-panel status/alarms, event & trend logging, and options for remote supervision (where equipped) so operators can review readings and adjust setpoints without a site visit. Standard I/O—relay outputs, alarm contacts, and 4–20 mA signals—makes it straightforward to pair with peristaltic pumps, erosion feeders, CO₂/acid systems, VFDs, and building management systems. The result is stable water quality and repeatable plant behavior with fewer chemistry swings and less downtime.

Key highlights

-

Unified controller for PPM free chlorine + pH and filter/pump/heater automation

-

Proportional/PID dosing with dose limits, feed lockouts, and overfeed protection

-

Automatic backwash (time, ΔP, or flow triggers) with step timers and chemistry pause

-

Programmable relay outputs, alarm contacts, and 4–20 mA for integration (pumps, valves, VFDs, BMS)

-

On-panel alarms, event/history logs, and optional remote supervision for oversight and compliance

-

Supports pump-proof, heater enable/cool-down (“fireman”), and flow/level interlocks for safer operation

Exclusive PC7000 Features

The CHEMTROL® PC7000 controller includes all the features of the PC6000 plus the new PPM Sensor for true monitoring and control of Free Chlorine.

| Feed Control | Manual, ON/OFF, Proportional Feed, Timer |

| Calibration | 1, 2 or 3 points |

| Langelier Index | Scaling and corrosion alert |

| Shock Program | Superchlorination and dechlorination |

| Savings | Chemical and energy saver programs |

| Failure Analysis | Dynamic Probe Testing with sensor failure warning for ORP and pH |

| Data Logging | On-board memory for 1,000 tests |

| Data Printing | Real-time with data logging or downloading from storage memory |

| Units | US and metric systems |

| Passwords | Security protection with ten 5-digit codes with 3 different access levels |

| Clock | 24-hour universal clock/calendar |

| Battery | Maintains all settings in case of power shutdown |

| Warranty | Five (5) years warranty on PC boards |

PC7000 Technical Specifications

- ORP readout in millivolts with programmable oxidizer feed control

- SANITIZER readout in ppm or mg/l with programmable sanitizer feed control

- pH readout with programmable acid and base feed controls

- Temperature readout in degrees Fahrenheit or Celsius with programmable heater control

- Bypass line with in-line filter, flow meter, safety flow switch, two control valves and sampling valve

- Sensor cleaning with programmable acid wash control

- Remote alarm (hot or dry contacts)

- Conductivity readout in microsiemens and TDS readout in ppm or mg/l with programmable dump valve control

- Programmable Feed Control for three (3) chemical additives

- Electronic Water Level Sensor with automatic fill valve control

- Flow Sensor with saddle clamp mount

- Seven-day main pump program

- Two (2) pressure sensors (influent and effluent) in psi or kg/cm2

- Six (6) relays for programmable sequential filter backwashing

- Data/Voice/Communication Modem

- CHEMCOM® remote computer software for Windows

- Remote Telephone Control of activator modes

- Telephone Alarm Callouts to six (6) memory-stored numbers

- Rain and splatter proof NEMA Type 3R fiberglass cabinet.

Options

- OPTION ETHCOM: Full duplex remote computer operation with Ethernet / Web-access communication.

- OPTION 420M: 4-20mA signal (4-channels) for monitoring display outputs.

- OPTION BMS: Modbus/BACnet-protocol communication for Building Management Systems.